The management of physical assets has undergone a radical transformation in the digital age. Historically, facility managers relied on manual logs and reactive repairs. Today, the integration of asset maintenance management software with real-time building data has created a new standard for operational excellence. By moving from a "fix-it-when-it-breaks" mentality to a data-driven strategy, organisations can significantly extend equipment lifecycles and reduce overheads.

At the heart of this evolution is the ability to connect disparate building systems. For a modern Smart Building, the goal is to create a seamless flow of information between the plant room and the dashboard. This connectivity is the primary enabler of advanced maintenance strategies, allowing technical teams to predict failures before they occur and optimise performance with surgical precision.

Maintaining a building ensures its durability, energy efficiency and the comfort of its occupants. Breakdowns, unforeseen damage and ageing equipment and materials inevitably lead to deterioration of the building and its interior. So it's essential to keep them in good condition.

Understanding Predictive Maintenance in Smart Buildings

To truly grasp the value of modern software for maintenance management, one must first understand the shift in methodology. In the past, maintenance was often viewed as a necessary cost center. Now, through the lens of IoT and advanced analytics, it has become a strategic lever for value preservation and energy efficiency.

What is predictive maintenance?

If you are asking what is predictive maintenance, it is a technique that uses data-driven, proactive evaluations to determine the condition of in-service equipment. The goal is to predict when maintenance should be performed. This approach offers cost savings over routine or time-based preventive maintenance because tasks are performed only when warranted by the actual state of the asset.

Unlike traditional methods, predictive maintenance solutions rely on continuous monitoring of variables such as temperature, vibration, and power draw. When an asset maintenance management software platform receives data indicating a deviation from the norm, it triggers a maintenance action. This ensures that the building remains operational and efficient 24/7.

Predictive maintenance vs preventive maintenance

The debate of predictive maintenance vs preventive maintenance is central to facility management. Preventive maintenance is a time-based approach (e.g., changing a filter every six months). While better than being reactive, it often leads to "over-maintenance,"

The different types of maintenance

There are three main types of maintenance commonly used in the construction industry:

- Corrective or curative maintenance

- Preventive maintenance

- Predictive maintenance

Corrective maintenance is carried out after a breakdown or malfunction has occurred, often as a matter of urgency.

Preventive maintenance, on the other hand, is carried out according to a predefined schedule, based on knowledge of the theoretical wear and tear of the equipment; the aim is to intervene before a breakdown occurs.

That leaves predictive maintenance, which, far from replacing the previous two, is on the contrary a recent and highly effective complement.

Definition of predictive maintenance

Predictive maintenance is distinguished by its ability to prevent breakdowns and predict when equipment failure may occur.

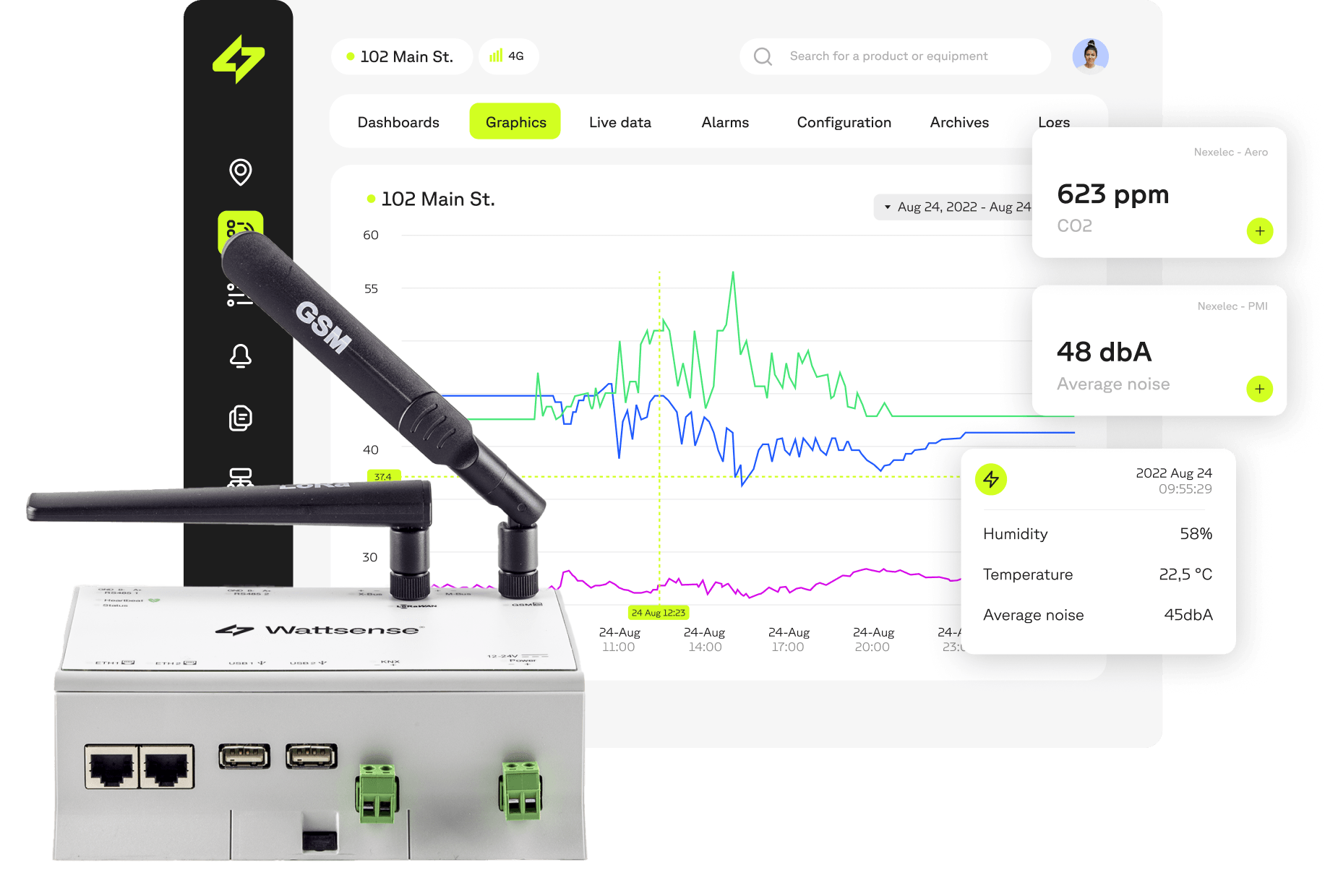

Predictive maintenance benefits from technological advances such as IoT (Internet of Things) devices combined with connectivity solutions and SaaS platforms. These technologies enable real-time analysis of data and the use of remote alarms to spot the warning signs of equipment failure.

This proactive approach makes it possible to anticipate breakdowns by planning maintenance operations in advance. By transmitting alerts remotely when risky equipment behaviour is detected, teams can act quickly to resolve problems before they become critical, ensuring continuity of operations.

In the building sector, predictive maintenance can be applied to any system, such as heating, ventilation and air conditioning (HVAC), lighting or lift operation. Automating and centralising data in a connected management system enables real-time monitoring and rapid intervention.

Predictive maintenance vs preventive maintenance

The debate of predictive maintenance vs preventive maintenance is central to facility management. Preventive maintenance is a time-based approach (e.g., changing a filter every six months). While better than being reactive, it often leads to "over-maintenance," where parts are replaced while still functional, or "under-maintenance," where a part fails between scheduled visits.

Comparing preventive vs predictive maintenance reveals that the latter is far more resource-efficient. While preventive maintenance software helps schedule routine tasks, predictive maintenance software uses live data to justify interventions. By moving to a predictive model, facility managers can reduce maintenance costs by up to 25% and decrease equipment downtime by as much as 35%.

The role of predictive maintenance machine learning

The true "intelligence" of modern systems comes from predictive maintenance machine learning. Algorithms are trained to recognise the "fingerprint" of an impending failure. For example, a specific vibration pattern in a chiller motor might be invisible to a human technician but is a clear warning sign to a machine learning model.

As the asset maintenance software collects more data over time, these models become increasingly accurate. They can distinguish between normal operational fluctuations and genuine mechanical wear. This level of sophistication is what allows large-scale property owners to manage complex portfolios with minimal on-site staff, relying on the software to flag only the most critical issues.

The Strategic Value of Asset Maintenance Management Software

Implementing a robust asset maintenance management software is no longer a luxury for Tier-1 buildings; it is a baseline requirement for any facility aiming for high performance. The software acts as a single source of truth, centralising all information regarding asset health, service history, and compliance documentation.

From planned maintenance software to predictive solutions

The industry is moving away from basic planned maintenance software, which serves as little more than a digital calendar. Modern equipment maintenance software must now act as an active participant in building operations. It should not only tell you when to fix something but how it is currently performing.

The transition from a simple preventive maintenance program software to a comprehensive predictive platform involves integrating live IoT feeds. This allows the software to move beyond static schedules and respond to real-time stress on the building’s infrastructure, such as increased HVAC load during a heatwave.

Benefits: Reducing downtime and operational costs

The primary driver for adopting predictive maintenance tools is the bottom line. Unplanned downtime is incredibly expensive, not just in repair costs but in lost productivity and tenant dissatisfaction. By identifying a failing pump on a Tuesday afternoon via predictive maintenance software, you avoid an emergency shutdown on a Saturday morning.

- Cost Reduction: Minimise emergency call-out fees and expensive shipping for last-minute parts.

- Asset Longevity: Keep equipment running at peak efficiency to prevent premature wear.

- Energy Efficiency: A well-maintained asset consumes significantly less power.

- Compliance: Maintain a perfect digital audit trail for safety and environmental regulations.

Choosing the right equipment maintenance software for your facility

Selecting the right equipment maintenance software requires an assessment of your building's existing technical debt. Does the software support the protocols used by your boilers and meters? Can it scale across multiple sites? Most importantly, does it offer the interoperability required to talk to your IoT gateways?

A successful preventive maintenance software rollout depends on the quality of the data it receives. If the software cannot easily ingest data from the field, it remains a static database. Look for solutions that offer robust API integrations and support for a wide range of predictive maintenance solutions to future-proof your investment.

The Strategic Value of Asset Maintenance Management Software

Implementing a robust asset maintenance management software is no longer a luxury for Tier-1 buildings; it is a baseline requirement for any facility aiming for high performance. The software acts as a single source of truth, centralising all information regarding asset health, service history, and compliance documentation.

From planned maintenance software to predictive solutions

The industry is moving away from basic planned maintenance software, which serves as little more than a digital calendar. Modern equipment maintenance software must now act as an active participant in building operations. It should not only tell you when to fix something but how it is currently performing.

The transition from a simple preventive maintenance program software to a comprehensive predictive platform involves integrating live IoT feeds. This allows the software to move beyond static schedules and respond to real-time stress on the building’s infrastructure, such as increased HVAC load during a heatwave.

Benefits: Reducing downtime and operational costs

The primary driver for adopting predictive maintenance tools is the bottom line. Unplanned downtime is incredibly expensive, not just in repair costs but in lost productivity and tenant dissatisfaction. By identifying a failing pump on a Tuesday afternoon via predictive maintenance software, you avoid an emergency shutdown on a Saturday morning.

- Cost Reduction: Minimise emergency call-out fees and expensive shipping for last-minute parts.

- Asset Longevity: Keep equipment running at peak efficiency to prevent premature wear.

- Energy Efficiency: A well-maintained asset consumes significantly less power.

- Compliance: Maintain a perfect digital audit trail for safety and environmental regulations.

Choosing the right equipment maintenance software for your facility

Selecting the right equipment maintenance software requires an assessment of your building's existing technical debt. Does the software support the protocols used by your boilers and meters? Can it scale across multiple sites? Most importantly, does it offer the interoperability required to talk to your IoT gateways?

A successful preventive maintenance software rollout depends on the quality of the data it receives. If the software cannot easily ingest data from the field, it remains a static database. Look for solutions that offer robust API integrations and support for a wide range of predictive maintenance solutions to future-proof your investment.

The Technical Challenge: Data Collection and Interoperability

The greatest hurdle in implementing asset maintenance management software is the "Data Gap." Most buildings are a patchwork of different technologies, some decades old. Bridging the gap between a 20-year-old chiller and a modern cloud-based dashboard is a significant technical undertaking.

The importance of high-quality data for predictive maintenance tools

Predictive algorithms are only as good as the data they consume. If a sensor provides noisy or intermittent data, the predictive maintenance tools will generate false positives or, worse, miss a critical failure. High-quality data collection is the foundational layer of any smart building strategy.

Reliable data must be timestamped, normalised, and consistent. This allows the predictive maintenance machine learning models to establish a baseline of "normal" behaviour. Without this foundation, even the most expensive asset maintenance software will fail to deliver a measurable Return on Investment (ROI).

Overcoming protocol barriers: BACnet, Modbus, and LoRaWAN

In a typical facility, devices speak different technical languages. Your HVAC system might use BACnet, your electrical meters might use Modbus, and your new wireless sensors likely use LoRaWAN. Traditionally, unifying these into one equipment preventive maintenance software required expensive custom gateways.

To solve this, managers need a universal translator. An IoT gateway that supports interoperability across these protocols is essential. By normalising all building data into a single stream (often via MQTT), you ensure that your planned maintenance software can "see" every asset, regardless of its original communication standard.

Connecting legacy equipment with Plug & Play solutions

The vast majority of the world's building stock is legacy. To bring these buildings into the era of predictive maintenance, we cannot rely on total system replacements. Instead, we must use Plug & Play solutions to "digitalise" existing assets.

Retrofitting involves adding wireless sensors to old machinery or using a gateway to extract data from legacy serial ports. This approach allows facility managers to implement preventive software maintenance and predictive strategies without the capital expenditure of a full plant room overhaul. It is the most cost-effective way to turn an old building into a smart one.

Predictive maintenance made easy

Our connectivity solution centralises data, enabling it to be viewed in real-time and remote alarms to be set up for intelligent, remote management of building maintenance. All without major works, equipment changes or additional complexity.

The benefits of advanced predictive maintenance

The adoption of predictive maintenance in building management is an undeniable step forward. It

- It considerably reduces maintenance costs by avoiding costly emergency interventions, while helping to extend the lifespan of equipment.

- By identifying minor malfunctions, it can be used to improve performance without human intervention, using adjustments, resulting in more energy-efficient buildings, greater comfort and greater safety. It also reduces the amount of human time spent on maintenance.